What is BENDING?

Bending

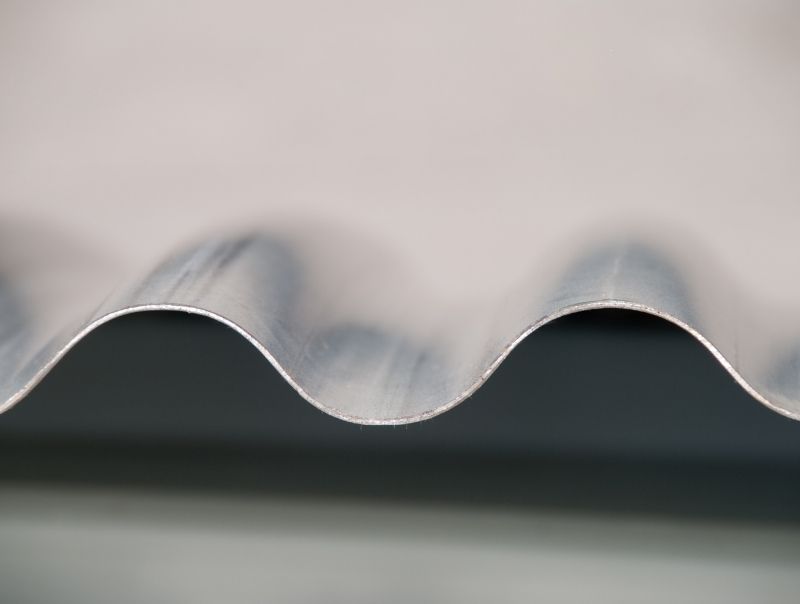

Metal Bending is the process of shaping metal sheets or bars with a specific bend radius and angle. This operation is commonly used to shape metal sheets, tubes, rods, or profiles for various industrial or construction purposes. Metal bending is considered an essential process to enhance the durability, aesthetics, and functionality of metal components.

Metal bending can be achieved through various methods:

- Simple V-Die Bending: Used to give a V shape to a metal sheet. The sheet is placed into the die and bent into a V shape to achieve the desired angle.

- Roll Bending: Metal sheets are passed through three or more rollers in roll bending machines to achieve the desired curvature radius.

- Hot Bending: In some cases, especially with thick metal parts, the material is heated before bending. Heat increases the metal’s flexibility, allowing for more complex bends.

- Tube Bending: Metal tubes are bent to the desired angle and radius using specially designed tube bending machines.

Some common machines used for metal bending include:

- CNC Bending Presses: Computer Numerical Control (CNC) machines that can be programmed for precise and repeatable bends.

- Roll Bending Machines: These machines enable the bending of sheet metal or tubes in a roll form.

- Hydraulic Presses: Large and powerful hydraulic presses are used for bending thick and sturdy metal parts.

- Profile Bending Machines: Designed for bending profile bars or various shapes.

Metal bending is applied in various fields, ranging from architectural projects to shipbuilding, automotive industries, and metal furniture production. It is an important technical process that allows for meeting diverse design and structural requirements while maintaining the strength and flexibility of the metal.